ACCRA - Alenia Capacity & Capability Rolling Assessment

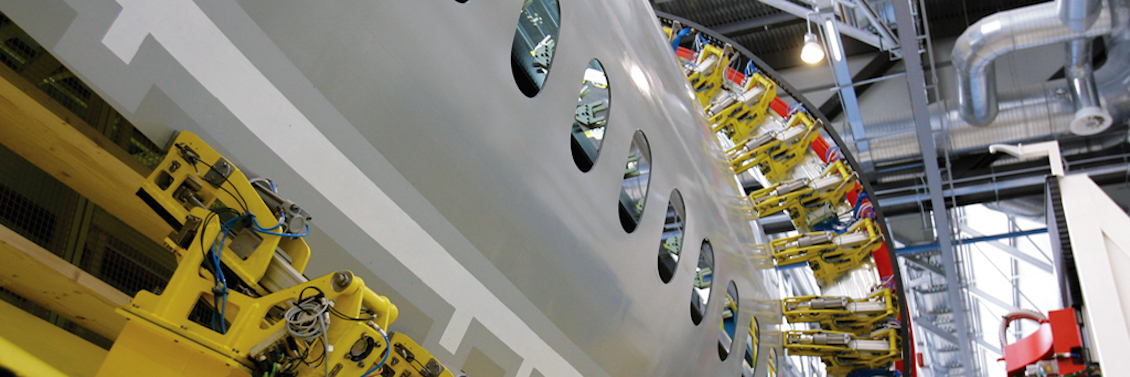

Source: Alenia Aeronautica

The assessment of the production capabilities and skills of our Supply Chain is crucial in order to secure an efficacious and efficient procurement process.

Knowing the strengths and weaknesses of our vendors helps us define our sourcing strategies. The process and method used, and the use of the right tools, are essential to guarantee a correct and complete assessment of each vendor's capability and potential. As already shown, the methodology proposed puts together various aspects that other methods studied previously had considered essential (Airbus and Boeing), trying to integrate specific requirements to complete the array of areas/activities assessed. In other words, the evaluation approach has shifted from being programme-driven, focused on the general aspects related to a specific programme or project, to being function-driven, i.e. capable of giving an overall picture of each vendor shared by all programmes and customers. The method used assesses both the efficacy, based on the reviewof available resources, and efficiency, based on the verification of their utilisation, in order to know the degree of optimisation reached by each vendor in production-oriented operating and management processes. Production capabilities may often be adjusted through a more effective use of the resources available, without resorting to more substantial and costly structural interventions.

The basic aspect of the methodology lies in the evaluation of vendors according to a global approach, not limited solely to production capability but extended to the factors that characterise their specific expertise in each area of industrial interest. In particular, management, organisational and technology capabilities are assessed, in addition to financial risks. The road map was traced along two parallel directions: to ensure the results from the production capability assessments required by the main customers (Boeing and Airbus) on emerging programmes, and to refine the method to meet our requirements through the development of process development and rationalisation tools.

By reviewing the preliminary information obtained, the general picture of each vendor was compared with their operational performance trying to associate the corresponding cause/effect relationship. The assessment focused on the identification of the main causes capable of affecting a vendor's operating performance, trying to remove the critical points found so as to guarantee the vendor's reliability. The contribution of all company departments was essential: they took part in the project and, thanks to their specific skills, allowed us to assess all the aspects described. The strength of our model is evidenced by the fact that it allowed us to achieve to fundamental business development goals, i.e. the verification of the sustainability of the production schedules required from vendors (rate readiness assessment) and a general assessment of the supply chain to be used as the basis for strategic vendor management and for initiatives aimed at its improvement.

The Alenia method, denominated ACCRA (Alenia Capacity & Capabilities Rolling Assessment), is composed of three main stages:

- Preparation: profiling each vendor based on the data available (size, technologies, relationship with Alenia, etc.) to ensure the team receives preliminary information;

- On site assessment: review of all the aspects related to the assessment of production capability and of the skills available for the activities involved;

- Definition of recovery action and follow up plan: an essential aspect of the assessment that allows to develop, by means of a root cause analysis related to the areas reviewed, an adjustment plan (quick wins) that will be monitored on a continuing basis by means of assessment follow-up sessions.

The method adopted is a rolling one: vendor assessments will be updated during follow-up sessions to take into account changes that may have occurred (changes in production workloads or in the organisational structure, new technologies, etc.).

Rosario Neri

Procurement & Supply Chain

Supply Chain Planning

Tags: Supply Chain Management, Alenia Aermacchi, Company Assessment, Aerospace