3-D Printing Benefits Break Through Aerospace Industry

Source: Paris Air Show 2015

3-D Printing (Additive manufacturing) technology is a major theme at 2015 Paris Air Show.

As larger parts can be delivered at lower cost through 3-D printing processes that promise significant improvements in production flexibility, aerospace and defense industry is preparing for a new technology leap.

3-D printing enables aircraft parts to be made in various different locations. This simplifies supply chains and creates more economical warehousing of parts, while manufacturers are encouraged to become more innovative in design. A supply chain normally taking 14-18 months could be shortened to some weeks – a huge benefit in saving working capital. Also, manufacturers can produce a part where and when they need it. On the other hand, 3-D printing equipment and processes require significant investments that result in higher direct costs than traditional manufacturing techniques. This could be mitigated by reducing total costs by means of the increased flexibility that includes the ability to produce parts in multiple locations closer to customers.

Parts can be made lighter without losing strength, and technology improvements allow more materials to be “printable”. In addition to the plastics and photosensitive resins that have been used so far, new applications include ceramics, glass, metals and thermoplastic composites infused with carbon nanotubes.

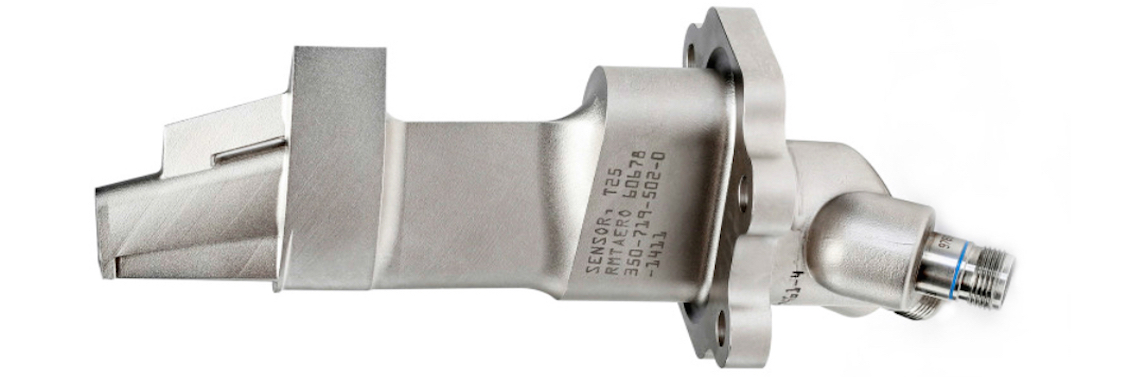

A new entrant is GE Aviation that included additive manufacturing in its Auburn faciity in Alabama to produce the housing of a temperature/pressure sensor located in the inlet to the high-pressure compressor of the GE90 turbofan engine. This has been the fist part of the kind certificated by the FAA (www.gereports.com/post/116402870270/the-faa-cleared-the-first-3d-printed-part-to-fly).

Another item is the fuel nozzle that will be additively manufactured for inclusion in the CFM LEAP jet engine for commercial single-aisle aircraft, which is now being tested. It is just a start, but the company is looking at what is being promised to become feasible 5-10-20 years ahead in terms of reducing weight, number of parts and overall complexity of assemblies, as well as product durability. New approaches are under study also to improve 3-D printing machines to allow increased output rates. A new design mentality is required for production using additives: it’s a matter to think in terms of layered additive processes instead of traditional subtractive techniques.

Additive technology is presently used to produce small components, and the process is not flawless, as human monitoring and intervention is still essential for quality control. Though allowing more freedom in the geometrics of products, their surface finish can be a bit rough and this needs further processing.

Another issue is the slow production rate that imposes to focus on high added-value components. Prospects are to have the rate of production made 5-10 times faster in ten years. GE expects to be able to use 3-D printing to produce around 45,000 pieces of the same part per year, and this might reduce the cost of producing a fuel nozzle by three-quarters, as it will be made in one piece rather than by assembling two dozen pieces.

In past May, a small (30 x 20 cms) jet engine produced at GE Aviation’s Additive Development Center near Cincinnati was tested up to 33,000 rpm

(www.gereports.com/post/118394013625/these-engineers-3d-printed-a-mini-jet-engine-then).

UTC Aerospace Systems (http://utcaerospacesystems.com) recently opened a new materials research laboratory in Windsor Locks, in an effort to introduce advanced additive manufacturing for aero-structures. A list of around 100 part numbers that could be produced by 3-D printing has been defined, including items such as brackets, impellers, rotors, fuel injectors and heat exchangers. Advanced metals such as nickel and titanium are likely to offer greater potential than plastics. Some parts can be built up from titanium wire rather than machined out from a titanium block.

The main limiting factor is still the fairly small size of the 3-D printing stands (around 0,3 liters). Multiple laser and optical systems in a single machine are also sought in second/third-generation equipment as well as tailor-made materials.

3-D printing is intended to bring significant benefits to spares and service provision by optimizing supply chain. Though presently the impact is limited as most aircraft do not have any parts made from additive manufacturing. Other challenges are posed by having to ensure that exactly the right 3-D model is used for additive manufacturing to meet airworthiness requirements and to protect intellectual property. 3-D printing is expected to take the same route in aerospace manufacturing that robotics did. First concerns were safety issues.

The new technology is likely to change the manufacturers’ attitude about whether to build or buy a part because there is no labor rate to be taken into account. All the components of the full life cost are to be considered, from digital design to production and product support.

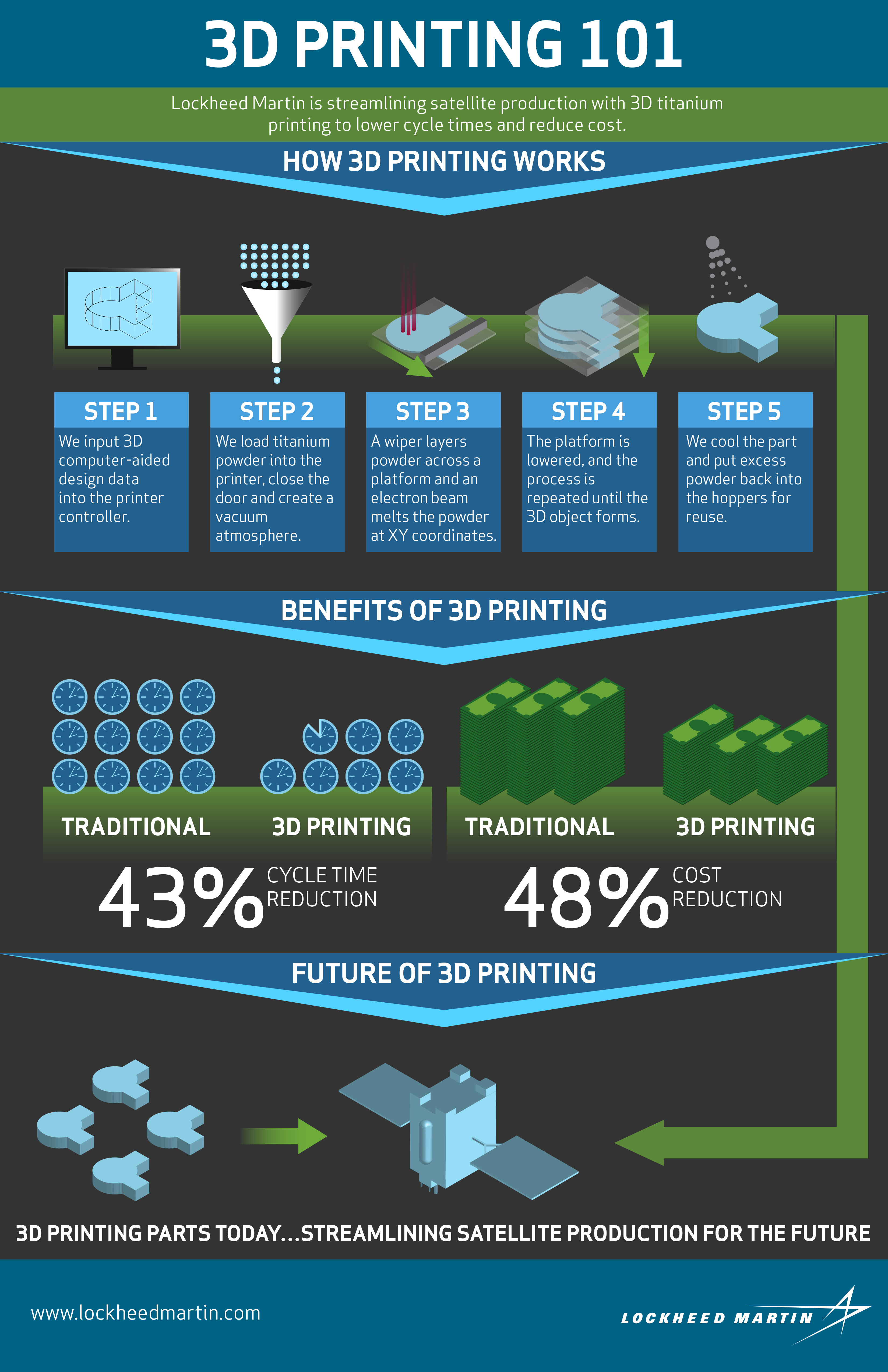

Lockheed Martin has been developing and implementing many applications of 3-D printing (a video can be seen in https://www.youtube.com/watch?v=qLJ8iUZCx0o), including the Sciaky Electron Beam Direct Manufacturing (EBDM) process which utilizes wire-feed electron beam welding technology to build parts up, layer by layer. Parts manufactured with this process can range up to 5.8 meters in length and 1.2 m in width and thickness. In collaboration with the U.S. Department of Defense, Cincinnati Tool Steel and Oak Ridge National Laboratory LM now wants to go further by developing a project aimed to achieve the capacity to 3-D print the endo- and exo-skeletons of the F-35 fighter. Panels of wings, internal structural parts with embedded wiring and antennas are included. Computerized controls to move the printers would be needed for the process.

The advantages of 3-D technologies in aircraft manufacturing are summarized in a Lockheed Martin infographic picture:

Source: http://www.lockheedmartin.com/content/dam/lockheed/data/corporate/photo/features/2014/3D-Printing-Infographic.jpg

In the commercial aircraft industry, in line with the new logistic strategy of the Airbus Group to maximize flexibility in the supply chain with the aim of avoiding delays, Minnesota-based additive manufacturing specialist Stratasys (www.stratasys.com) has already delivered over 1,000 3-D printed parts for the new A 350XWB long-range airliner.

Also Boeing has been exploiting the Stratasys process to build aircraft parts. More recently the Seattle air-framer has filed a patent application for its 3-D printed aircraft parts and is also trying to patent the entire system around it including: “a parts library; a database; a parts management system; and a three dimensional printing system.” Boeing describes a method and apparatus for requesting, authorizing, printing, and even paying for aircraft parts under the simple title: Three Dimensional Printing of Parts.

Andrea Artoni

AeroStudio

Tags: Aerospace & Defense, Paris Air Show - Le Bourget 2015, 3-D Printing Aerospace Industry