Berco moves towards OHSAS 18001 Safety Management System

Source: Berco News 64 > December 2012

In line with ThyssenKrupp directives, Berco has decided to start introducing an OHSAS 18001 certified Occupational Health and Safety Management System.

This will lead to improvements over the coming years, in terms of both safety and working methods, based on a philosophy of continuous improvement. The Occupational Health and Safety Management System (OHSAS) is an organizational system that aims to achieve health and safety objectives in a company with the most suitable cost-benefit ratio.

The adoption of an OHSAS is not a legal obligation but a voluntary choice for any company - like Berco - that feels responsible for its own and others’ safety.

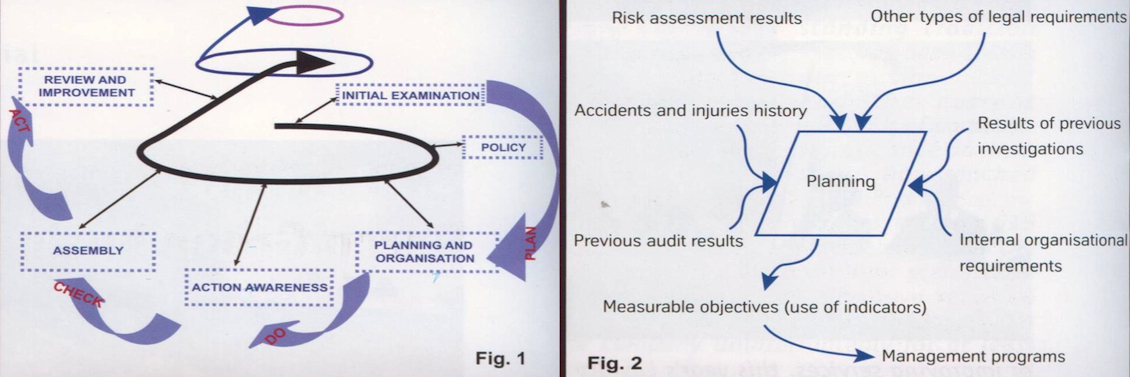

By means of a series of actions (fig. 1), the OHSAS aims to construct a set of principles, regulations and procedures, accompanied by the corresponding supervisory and control activities, which foresee and thus prevent the occurrence of occupational health and safety nonconformities.

Starting from an analysis (fig. 2) of all the critical situations in the company, and the monitoring of fixed objectives, the basic underlying principle of all the systems is created: continuous improvement.

Finally, the Occupational Health and Safety Management System (OHSAS) defines how the personal responsibilities, procedures, processes and resources within the organizational structure are to be identified, in accordance with binding health and safety regulations, in such a way as to make them more efficient and more fully integrated into the general activities of the company. The OHSAS 18001 model, if applied correctly, brings the following benefits:

- reduction of the number of accidents by prevention and control in workplaces classified as hazardous;

- reduction of the risk of serious accidents;

- reduction of material losses resulting from accidents and production stoppages;

- reduction of the INAIL (Italian National Institute of Insurance against Employment Injuries) health insurance premium;

- availability of an integrated management system covering aspects related to quality, the environment, healt and safety;

- meeting expectations with regard to public opinion, even more sensitive to issues regarding occupational health and safety.

A gradual process of change has been taking place at Berco for months on this specific theme, with the planning of courses, the dissemination of a safety policy and the scheduling of safety meetings and specific audits, with the aim of guaranteeing continuous improvement to both the company and its employees.

Also, in recent months, there have been a number of conformity pre-audits in all the Italian Berco factories, together with the other companies in the ThyssenKrupp group.

As well as at Berco, this same process is also taking place at ThyssenKrupp Elevator, Thyssen Krupp ENCASA, ThyssenKrupp Electrical Steel, UhdeNora and Rohm Italia.

Many activities have yet to be planned and there are still many tasks facing the company and its employees, at all levels of responsibility.

We are convinced, however, that health and safety are fundamental prerequisites for the company's success and that, with the daily commitment of all, Berco can become a better, continuously improving workplace.

Saverio Salvi

Prevention, Protection and

Environment Service Manager

Tags: ThyssenKrupp, Berco