Advanced engineering solutions and high-performance products

Source: Comer Industries Annual Report 2011

The high strategic value of New Product Development department of Comer Industries.

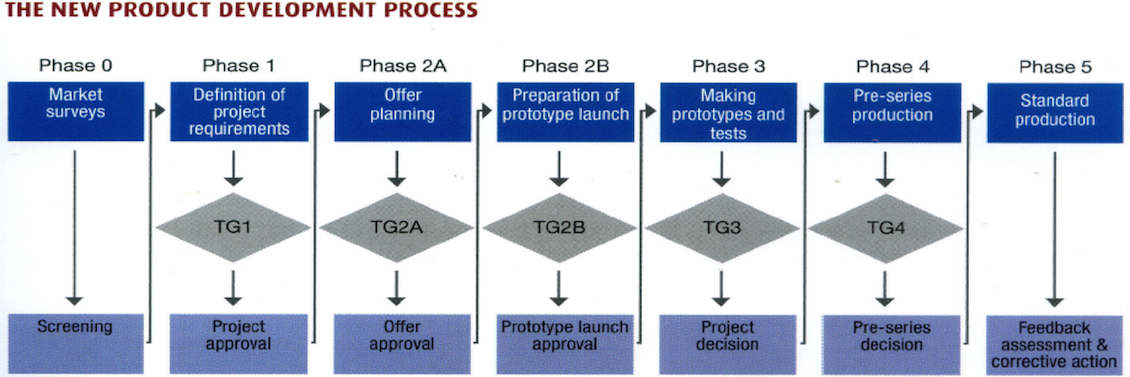

The New Product Development (NPD) department coordinates interfunctional processes for the development of new products, in compliance with ISO TS 16949 standards and based on the APQP (Advanced Product Quality Planning) method, able to sustain company growth and return, according to the long-term strategic plan.

The project leader in charge plans the various stages, controls progress, promotes interaction between departments, prevents critical situations and coordinates their resolution.

In 2011, about 120 projects were launched and 50% reached standard production.

The strategic value of the NPD department is clearly reflected in figures. Over the past 3 years, turnover from new products totaled nearly 90 million euros (+27% over 2008).

Product innovation

In 2011, Comer Industries presented many hi—tech products and systems designed to satisfy the high performance and reliability requirements of customers operating in the agricultural, industrial and renewable-energy sectors.

New S 228 differential axles

In 2011 , following a strategic market analysis, Comer Industries renewed its range by designing the new 8 228 rigid and steering differential axles, which are able to respond to the manufacturers demand in terms of energy saving and the cutting of harmful emissions.

The next axle applications include telehandlers, front loaders, compact loaders and construction-industry machinery in general. It can also be used for feed mixers, thanks to a dynamic capacity of up to 12,000 kg.

PG 1904 PR

The PG 1904 PR planetary drive, developed for a new wind generator model, has been designed to satisfy the demand for “yawing” applications (nacelle rotation around its own axis) with extreme compactness and outstanding performance.

Steel planet carriers and ring gears inserted in the box with a tight fit, in which two stages at a time can engage, obtaining a compact, reliable and high-performance product.

The new drive will be used in new generation turbines, created with the Direct Drive system (multipole low-speed generator) to considerably reduce the number of components and, consequently, the weight and maintenance required by the nacelle for towers featuring the same power class.

The planetary drive has been conceived to equip 5 MW wind turbines and will be extended to the 2 MW and 7 MW range, thus confirming the market trend to prefer increasing|y—higher power machines.

CKD (Center Knife Drive)

In partnership with a leading manufacturer of agricultural and earthmoving machines, Comer Industries has developed an innovative drive for corn headers. The new center knife drive is positioned at the center of the header, between the cutting plane and the sliding block; the system works on the same basis as the two opposing knife drives used in largest headers but eliminates the vibrations they can cause by continually keeping the opposing knifes perfectly synchronized, thus granting an increased cutting width.

The use of aluminum to reduce weight and the input, providing for a punctual speed adjustment and stop during turning operations, helps improve harvesting and cuts consumption.

Tags: Comer